Description

BEP Contour Matrix Gas Detector with Control

The Contour model LPG, Petrol and CNG detector is the product of continuing research and development, which BEP Marine Ltd devotes to their product range. The 600 series detectors use the latest in solid state technology available, with a microprocessor control head connected to the latest in sensor technology. The 600 series detectors have the capability to control two sensors with both visual and audible alarms. There is a test switch to check the operation of the sensors with indicators for fault detection.

The 600-GDL has provision for the connection of an external alarm, bilge blower, gas on/off valve and manual override to disable faulty sensor. There is no power on/off switch provided in either unit. It is intended that for maximum protection the unit should be on all the time while you are on your boat or vehicle.

Features

- Self testing capability

- Microprocessor control

- Dual sensor capability

- Provision for an external alarm

- Provision for automatic bilge blower switching

- Automatic shut-off solenoid control with Pulse and Hold circuit technology for low power draw(600-GDL only)

- Manual override – Important: Disables gas detector (600-GDL only)

Specifications

- Voltage: 600-GDL 10-15V DC

- Current: Total 350mA Max

- Alarm: 20% LEL (Lower Explosive Limit)

- Current at outputs: 800mA Max (per output)

Note: If you are using a solenoid valve other than BEP’s VR2. The solenoid current draw must be checked to make sure it is 800mA or less at 12.5 volts.

Fault Detection

The nominal alarm point of the 600 series is 20% of the LEL (Lower Explosive Limit) of LPG/CNG in Air. In the event of a gas leak and the alarm activating, close the manual valve on your gas bottles and open hatches to ventilate the area. All fans and blowers used to ventilate must be ignition protected types.

In the event of a sensor being contaminated, damaged, cable shorting or a faulty connection, the amber light will come on for the particular sensor. If the sensor fault persists then the sensor could be damaged and will need to be replaced. In detecting LPG the sensor can also detect hydrocarbons in other products such as cleaners and strong adhesives, this can cause nuisance alarms.

Cautions When Using Gas Sensors

- Exposure to silicone vapors can irreversibly inhibit sensor sensitivity.

- Highly corrosive environments can cause irreversible damage to the sensor.

- Water, freezing, and high-density gas exposure can adversely affect sensor performance.

- The sensor can detect hydrocarbons in other products, causing nuisance alarms.

Important Notes

- If the sensor gets wet, it becomes inoperable and must be replaced.

- For units with S/N before J48494, an 82k resistor must be fitted between terminals G and R on the back of the meter case.

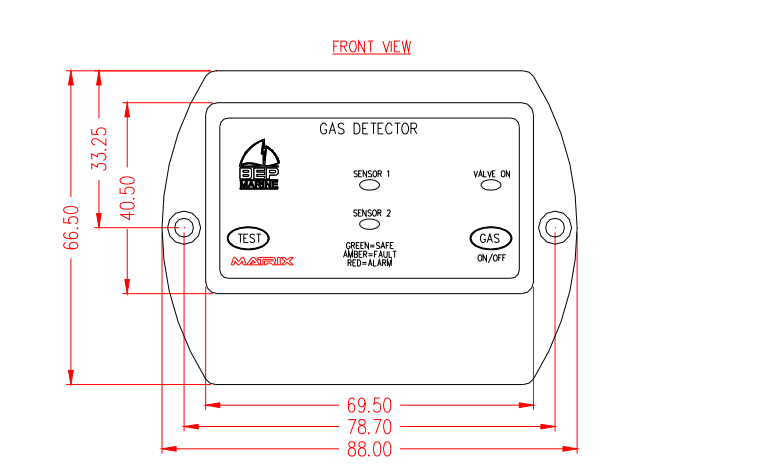

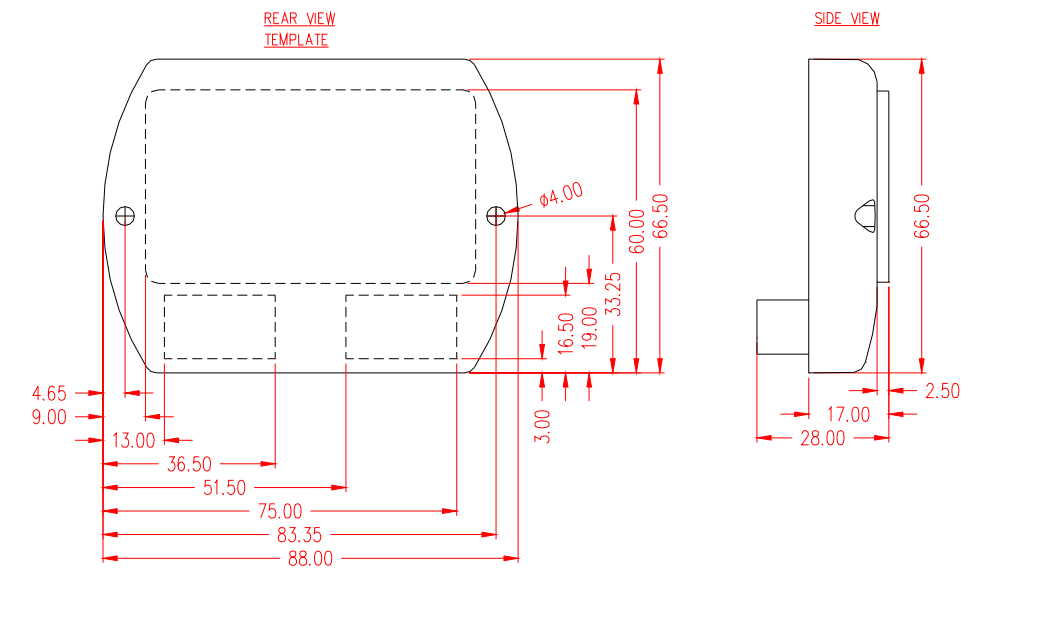

Dimensions